Happy 244th Birthday!

It's independence day! And about a month since my last update. Steady progress due to quarantine, knocking out little projects every day.

Empennage Attachment

I think in the last month, I wrapped up the empennage attachment section finally. Got a DC power adapter to bench test the trim servo, and it's incredibly satisfying when it actually moves. Not 100% done, as my trim tabs don't go the full 35 degrees nose down, but I'm leaving that for another day. I think I may need to pull the cables out of the HS and adjust the travel, which means I need to redo all my work there, including reattaching the cover plates and I just don't have the energy to tackle that again right now. Definitely have reverse travel at the top end, where my right trim tab continues to travel up and my left trim tab starts deflecting down again, so will need to look at that too.

Fuel system install

Started tackling the fuel system install too this month. Put in a tunnel access panel on the passenger side, which is all I think I need since only my fuel pump is going into this space. My two fuel filters are instead going to go in the wing root of each tank, which should allow for easier maintenance in the future and less spilled fuel in the cockpit. TS Flightlines put together my hose kit, and I'm installing per their install documents, planning for an SDS system. If you take this route, you'll need LP4-4 rivets for the fuel pump attachment angles as the thickness with the reinforcement plate is about 0.19 just a bit over the grip length of the LP4-3 rivets Vans specs in this location. Also, instead of following the instructions and cutting out the stock fuel selector attachment piece to fit the Andair valve, I cut a piece of aluminum and riveted it on instead. IMO this is superior as you don't need to do extra work cutting metal and the stock piece acts as a doubler.

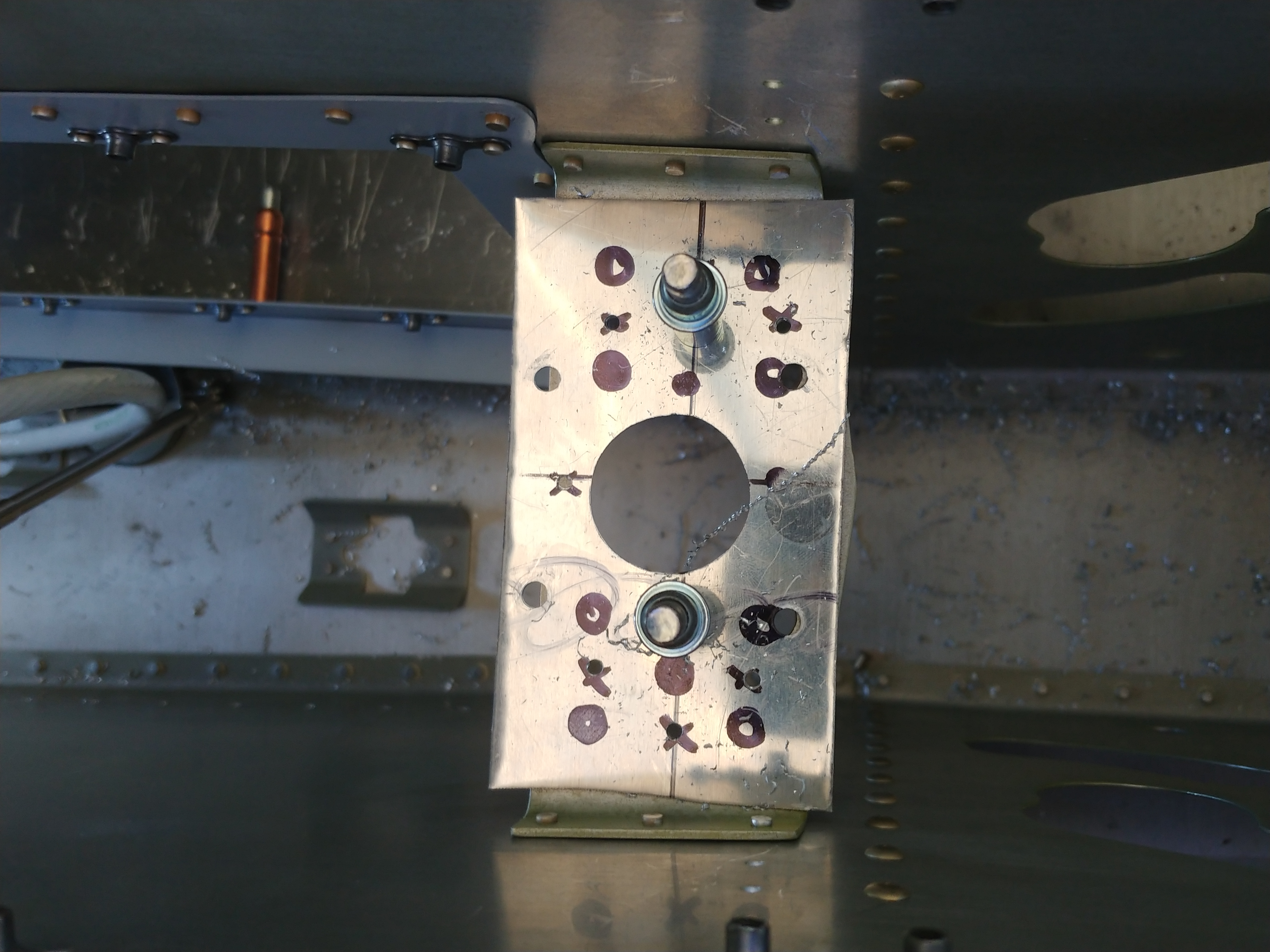

Here's a shot of the new piece I fabbed:

The circles are traced from the stock fuel selector attachment piece. Then I drew X's where I would drill rivet holes, put the new piece on top of the stock attachment plate and match drilled.

Next up, need to work out which hoses go where and put the fuel system in.