Cabin Top Riveted

Have been delaying this step for a long time now since I wanted to get as much done as possible in the tailcone before closing everything up. However, finally realized there would always be more to do. I got the ELT installed, NACA vents cut and installed, and then proceeded to close and rivet up the tailcone and cabintop. In the future, I'm still planning on installing the transponder and #2 COM radio there, and at least one battery will need to go back there. But that's future me's problem. Build on!

Panel Installation

In the same vein, starting to install the panel today. I had the panel built by Pacific Coast Avionics, using an Aerosport 310 Panel and it was delivered a month or so back.

All I did this weekend was to mount the aluminum panel subframe onto the fuselage.

The instructions from Aerosport are unfortunately wrong for the product I received.

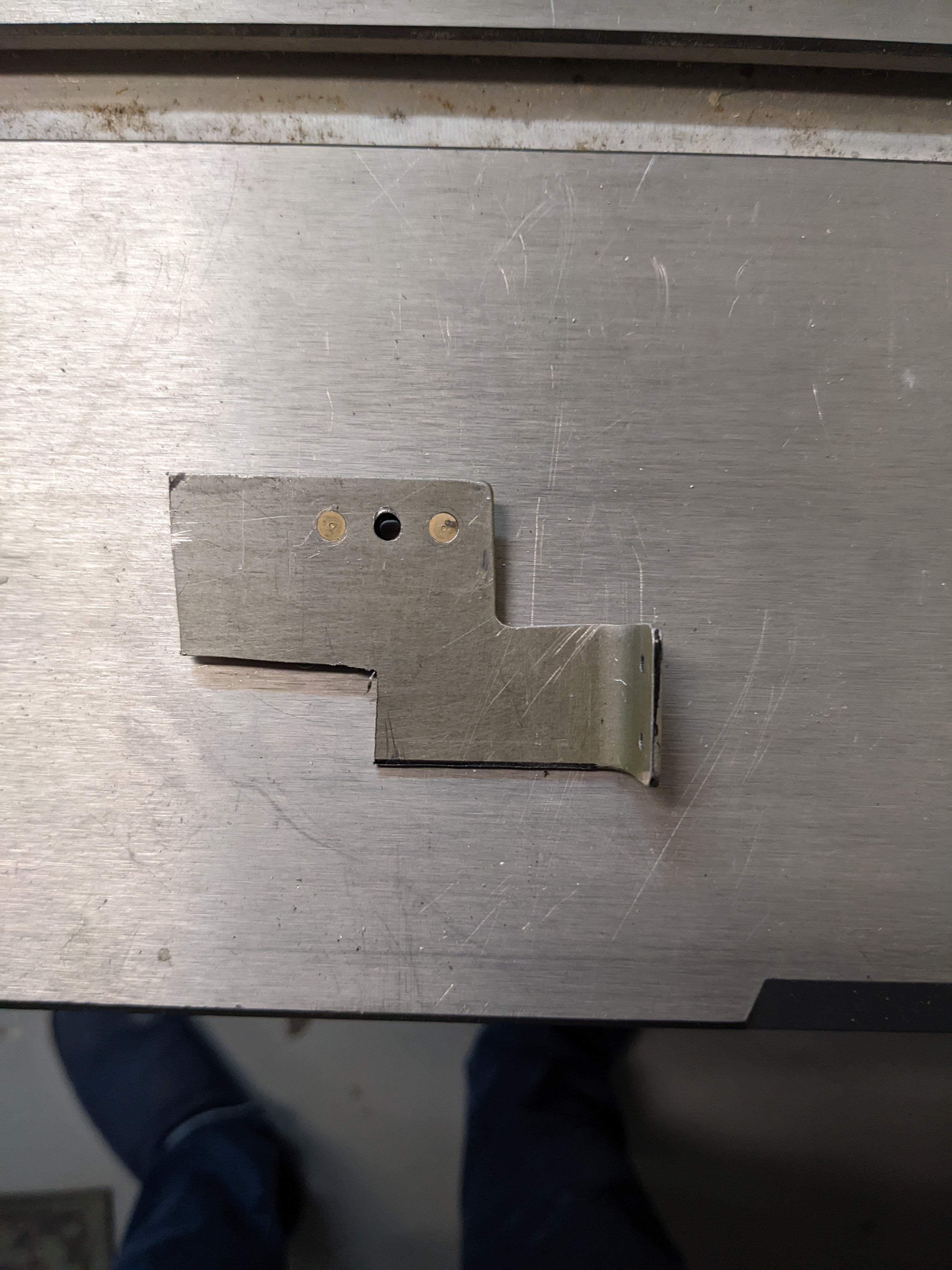

Instead, you'll notice the aluminum frame already has a hole drilled around this location. If you cut per the instructions, you can't capture this hole and you'll need to file away half of the height to actually fit behind the frame. Instead, cut straight from the top of the F-1003B bottom brace and include the nutplate already in place like this

You can see the pre-drilled holes in place on the frame.

You can see the pre-drilled holes in place on the frame.